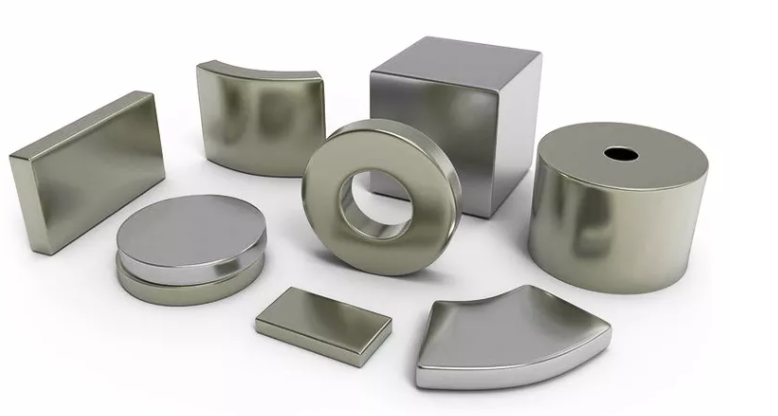

1. Neodymium magnetum ex pulvere mixto neodymii, ferri, et boron, quae simul sub magno calore et pressione insunt, ad operis formam formandam fieri solent.

2. Puluis mixtus in fomacibus seu receptaculo ponitur et ad caliditatem elevatam calefacta ita ut liquare et fuse incipiat.

3. Materia cum punctum liquescens attingit, hac temperatura per aliquod temporis spatium tenetur, donec in unam partem nullo hiatu aut rimas inter particulas solidatur.

4. Postquam solidificatio facta est, magnes machinari potest in eius desideratam figuram et magnitudinem, variis instrumentis incisis utens, sicut machinas molas vel lesta secundum applicationem specificationum.

5. Magnetis margines tunc leves esse possunt, si desiderantur antequam obductis ad laminam tutelam, ut nickel vel zinci, ad corrosionem resistentiae faciendae.

Plures processus details, quaeso, benigne vide chartulam mugilem;

| Nec. | Processus flow | Productio Step | Operatio technica |

| 1 | Rudis Material inspectionis | 1.ICP-2.chemical Analysis-3.Analyser(C&S) | Rohs Detection Compositio Test Puritas Analysis |

| 2 | Rudis Material Pre-curatio | 4.Sawing- 5. Drying- 6.Impact Purgatio | Ferrum serrare Hot Air Siccatio Impact Purgatio |

| 3 | Imperium ingrediens | 7.Ingredient Imperium | pondera Batching Mix Rudis Material |

| 4 | Exue iactis | 8.Vacuumizing-9.Melting-10.Casting | Vacuumizing Exustio Smelting Conjectio |

| 5 | Consectetuer Decrepitation | 11.Pre-tractare-12.Vacuumizing-13.Add Hydrogenium | Pre-tractans Vacuumizing Demoliri per Hydrogenium |

| 6 | Milling | 14.Shattering-15.Grinding-16.Jet Mill-17.Granularity Control | Shattering molendum Jet Mill Rogationis mensurae |

| 7 | Urgeat | 18. Pulvis pondus -19.Pre-pressio – 20.Pressing -21. Isostatic urgeat | pulveris pondus Pre-pressing Urgeat Isostatic urgeat |

| 8 | Sintering | 22.Vacuumizing- 23.Sintering -24 Calor curatio | Vacuumizing Sintering Calor curatio |

| 9 | inspicienda | 25.BH curva-26. PCT-XXVII. Densitas test -28.Roughcast inspectionem | Magna mensura Temperature coefficiens test PCT Densitas mensurae inspicienda |

| 10 | Machining | 29. Grinding -30.Wire cutting-31.Inner ense cutting | molendum Filum secans Interiorem ferrum sectione |

| 11 | QC specimen test | 32.QC test specimen | QC specimen test |

| 12 | Chamfering | 33.Chamfering | Chamfering |

| 13 | Electroplating | 34.Electroplating Zn 35. Electroplating NICUNI 36.Phosphating 37. Chemical Ni | Electroplating Zn Electroplating NICUNI Phosphating vel Chemical Ni |

| 14 | Coing Inspectionis | 38.Thickness-39.Corrosion Resistentia -40. Adhaesiveness-41.-Tolerantiae Inspectionis | Crassitudo Corrosio Resistentia Adhaesiveness Inspectionis tolerantia |

| 15 | Magnetization | 42.Complete Inspection- 43.Marking- 44.Arraying/Involution- 45.Magnetizing | Integram inspectionem Vestigium Dispositis / Involution Magnetizing Magnetic Fiux Test |

| 16 | stipare | 46. Magnetic Flux- 47.Bagging- 48. Pack | Bagging stipare |

Post tempus: Feb-15-2023